A Vehicle Air Compressor is an essential component in modern vehicles, serving multiple purposes ranging from powering pneumatic tools to inflating tires and operating air suspension systems. Understanding how a vehicle air compressor works and its applications is crucial for automotive enthusiasts, fleet operators, and mechanics alike.

What is a Vehicle Air Compressor?

A Vehicle Air Compressor is a mechanical device that converts power from a vehicle's engine or battery into compressed air. This compressed air can then be used to operate various air-powered devices within the vehicle, such as brake systems, air suspension, and even tire inflators. By storing and regulating pressurized air, these compressors provide reliable performance and enhance vehicle functionality.

Key Components of a Vehicle Air Compressor

- Motor or Engine Drive: Powers the compressor, either electrically or mechanically.

- Compressor Pump: Compresses atmospheric air into a smaller volume to generate high pressure.

- Air Storage Tank: Stores the compressed air for immediate or future use.

- Pressure Switch: Regulates the compressor by turning it on and off based on air pressure levels.

- Air Filters: Ensure clean air intake to protect the system from debris and contamination.

How Does a Vehicle Air Compressor Work?

The operation of a Vehicle Air Compressor involves several key steps:

1. Air Intake

Atmospheric air enters the compressor through an air filter. This ensures that dust, dirt, and other particles do not enter the system and cause damage.

2. Compression Process

The compressor pump, powered by either an electric motor or engine belt, compresses the air. This process reduces the air volume while increasing its pressure, storing energy in the form of pressurized air.

3. Storage in the Air Tank

The compressed air is directed into a storage tank, where it remains until needed. The tank allows the system to provide a steady supply of pressurized air even when the compressor is not actively running.

4. Pressure Regulation

A pressure switch monitors the air tank and controls the compressor operation. When the air pressure falls below a set threshold, the compressor activates. Once the desired pressure is reached, it shuts off automatically, maintaining optimal performance and efficiency.

Types of Vehicle Air Compressors

Vehicle air compressors can vary based on design, power source, and application:

1. Electric Vehicle Air Compressors

These compressors run on the vehicle's battery and are ideal for smaller tasks such as tire inflation or powering small air tools. They are typically compact, portable, and easy to install.

2. Engine-Driven Air Compressors

Connected directly to the vehicle’s engine via a belt, these compressors provide higher airflow rates and pressures. They are commonly found in trucks, buses, and industrial vehicles for tasks such as braking systems and air suspension.

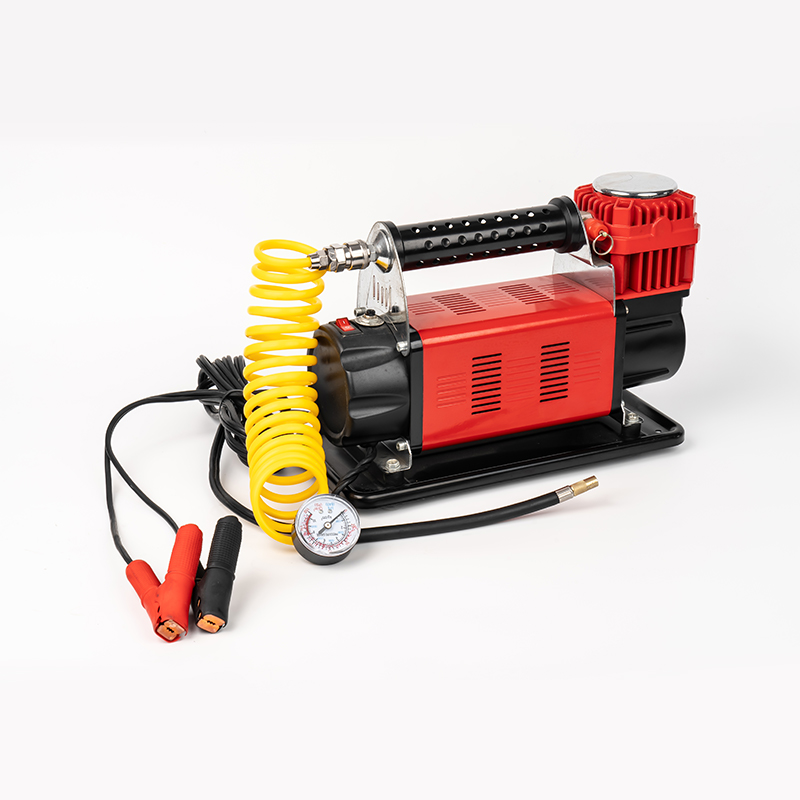

3. Portable Air Compressors

Lightweight and often battery-powered, portable vehicle air compressors are designed for emergency situations and roadside assistance. They are user-friendly and can inflate tires, sports equipment, or small pneumatic tools quickly.

4. Onboard Air Systems

Integrated into larger vehicles like RVs and commercial trucks, onboard air systems use multiple compressors and tanks to provide a constant supply of compressed air for heavy-duty applications. These systems support braking, suspension, and pneumatic accessories simultaneously.

Applications of Vehicle Air Compressors

A Vehicle Air Compressor has a wide range of applications, depending on the vehicle type and installed system:

- Air Brakes: Heavy-duty trucks and buses rely on air compressors for safe and effective braking performance.

- Air Suspension: Enhances ride comfort and load leveling in trucks, RVs, and luxury vehicles.

- Tire Inflation: Quick and convenient tire inflation ensures optimal performance and safety.

- Pneumatic Tools: Powers tools like impact wrenches, drills, and jackhammers for maintenance and repairs.

- Off-Road Vehicles: Supports off-road recovery equipment such as air lockers and inflators for tires in challenging terrains.

Maintenance Tips for Vehicle Air Compressors

Regular maintenance is crucial for maximizing the lifespan and efficiency of a Vehicle Air Compressor :

- Check Air Filters: Clean or replace air filters regularly to prevent dirt from entering the compressor.

- Inspect Hoses and Connections: Ensure hoses are free of cracks or leaks to maintain consistent pressure.

- Drain the Air Tank: Moisture can accumulate in the tank, so periodic drainage is necessary to prevent rust and damage.

- Monitor Pressure Levels: Ensure the pressure switch operates correctly to avoid overpressure or underperformance.

- Lubrication: Some compressors require oiling. Use the manufacturer’s recommended lubricant to reduce wear.

Advantages of Using a Vehicle Air Compressor

The benefits of a reliable Vehicle Air Compressor extend to both convenience and vehicle performance:

- Efficient Power Supply: Provides a consistent source of compressed air for multiple applications.

- Safety: Supports air brake systems and other critical vehicle functions.

- Versatility: Powers a range of pneumatic tools and accessories for on-the-go use.

- Cost-Effective Maintenance: Helps maintain tire pressure and vehicle systems, reducing repair costs and extending service life.

Common Problems and Troubleshooting

Even the most reliable vehicle air compressors may encounter issues over time:

1. Compressor Not Activating

Check battery voltage, fuses, and pressure switch settings. Ensure the motor is receiving power and that the air tank is not full.

2. Low Air Pressure

Inspect for leaks in hoses, fittings, and the air tank. Dirty filters or worn components may also reduce air output.

3. Excessive Noise

Noise may indicate loose components, worn bearings, or insufficient lubrication. Regular maintenance can prevent these issues.

4. Moisture in the Air Tank

Drain the tank regularly and install a moisture separator if necessary to prevent rust and system damage.

FAQ About Vehicle Air Compressors

Q1: Can a Vehicle Air Compressor run continuously?

Most compressors are designed for intermittent use. Continuous operation may cause overheating or damage. Always check the manufacturer’s specifications.

Q2: Are electric compressors powerful enough for heavy-duty applications?

Electric compressors are suitable for light to moderate tasks. For heavy-duty applications like air brakes or large pneumatic tools, engine-driven or onboard compressors are recommended.

Q3: How long does a vehicle air compressor last?

With proper maintenance, a vehicle air compressor can last several years. Regular inspection, cleaning, and lubrication are key factors.

Q4: Is installation difficult?

Portable electric compressors are generally easy to install and use. Engine-driven or onboard systems may require professional installation for optimal performance.

Conclusion

A Vehicle Air Compressor is an indispensable component that enhances vehicle safety, convenience, and functionality. From powering brakes and suspension systems to inflating tires and operating pneumatic tools, these compressors play a crucial role in modern automotive technology. Understanding their mechanism, types, applications, and maintenance ensures reliable performance and longevity, making them a smart investment for any vehicle owner or operator.